How we help

Not every day can be a record setting production day. Some days will be better than others. It becomes an issue when your days are more frequent than others.

Often times, you could be seeing scrap on your line from improperly setup hardware. Maybe a light accidentally got moved. Or maybe you have a new supplier who's parts don't run quite as well through the machine. Thats where we come in. With a decade of experience in direct machine vision system design and implementation, we have developed the skills to be able to improve your systems.

While our main expertise is in the Cognex InSight platform, we also specialize in Keyence's vision offerings.

- Review collected false rejects and verify there are no setup issues

- Analyze code to correct any programming faults

- Evaluate programming techniques, modify/optimize code causing false rejects

- Prepare necessary documentation for change control / validation

- Provide continued production support

Services

What we offer

Expertise

Our most commonly used Machine Vision softwares.

- All

- Cognex

- Keyence

- 2D

- 3D

- Barcode

- AI

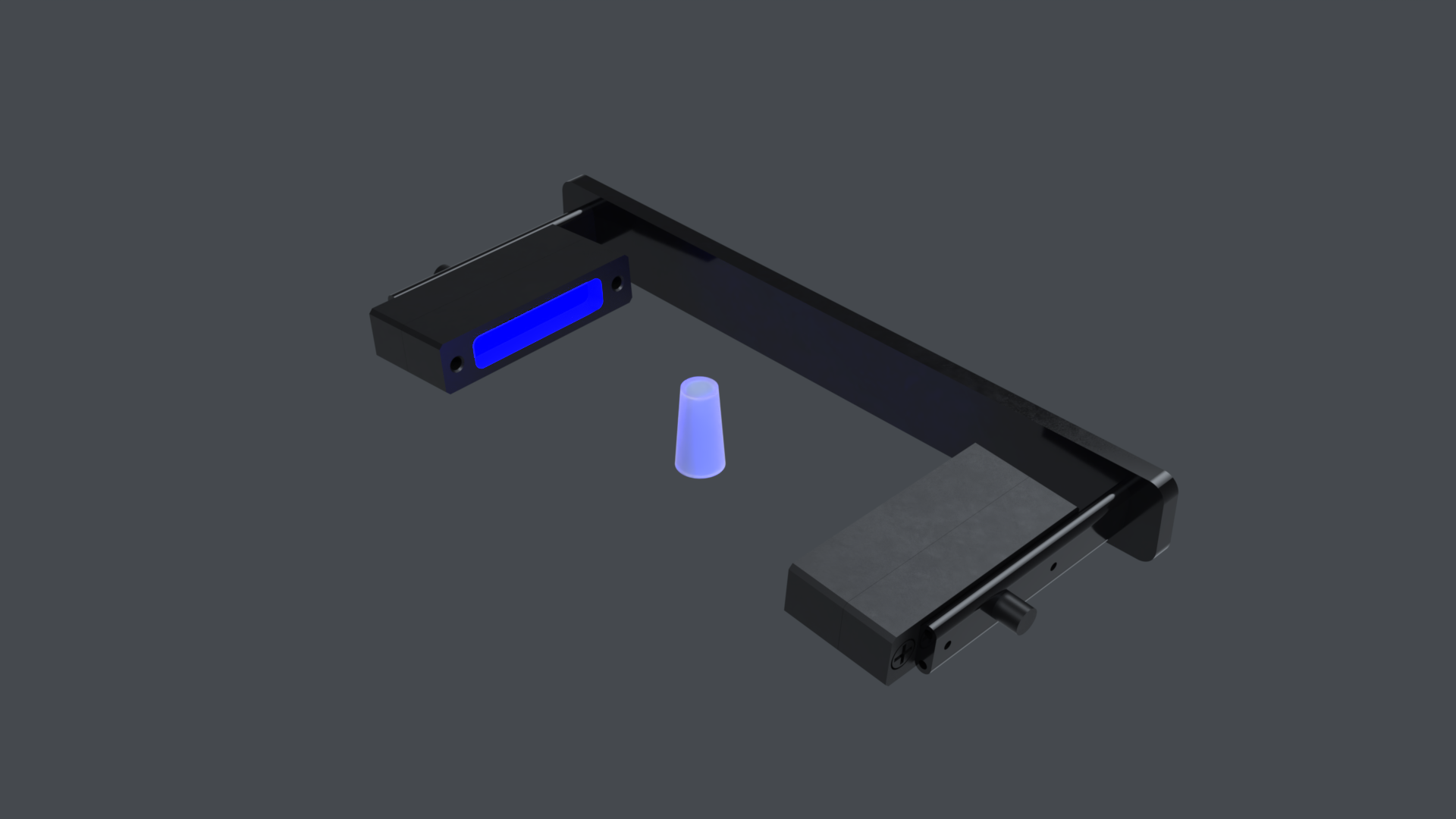

Simulations

In situations where it can be hard to make parts available for testing, we use 3d modeling to simulate different lights and how they will affect our inspections.

Frequently Asked Questions

Do you need live, on-site access to the machinery?

Nope. Everything we do can be done offline as to not interfere with production.

What happens if you can't improve my scrap rate?

You don't pay unless you are making more after our services.

Our vision systems are confidential?

We don't work without NDAs to protect both parties investments.

White Lab Automation

White Lab Automation